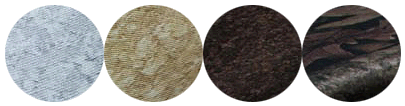

- Colorful Pattern Options (Galvanized, Harvest, Cork & Camo)

- Active Antimicrobial Treatment

- Matte Exterior Finish

- Air Porous Fabric (Custom Porosities)

- Standard Adjustable Flow Device (AFD)

- Standard Inlet Cover-Up Sleeve & Zippered Endcap

- Launderable

- 10 Year Warranty

Coronado™ : Patterned Designer Fabric - Quick Links

White papers

Presentation

Applications

Technical Specs.

PART 1-GENERAL

1.01 DESCRIPTION OF WORK:

A. Extent of non-metal ductwork is indicated on drawings and by requirements of this section.

B. Types of non-metal ductwork required for this project include the following:

1. Fabric Air Dispersion Products.

1.02 QUALITY ASSURANCE:

A. Building Codes and Standards:

1. Product must be Classified by Underwriter’s Laboratories in accordance with the 25/50 flame spread / smoke developed requirements of NFPA 90-A and are also classified in accordance with ICC Evaluation Service AC167.

2. All product sections must be labeled with the logo and classification marking of Underwriter’s Laboratories.

3. Product must be treated with an EPA registered antimicrobial agent.

B. Design & Quality Control

1. Manufacturer must have documented design support information including duct sizing, vent and orifice location, vent and orifice sizing, length, and suspension. Parameters for design, including maximum air temperature, velocity, pressure and fabric permeability, shall be considered and documented.

1.03 SUBMITTALS:

A. Product Data: Submit manufacturer’s specifications on materials and manufactured products used for work of this section.

B. Building Code Data: Submit UL file number under which product is Classified by Underwriter’s Laboratories for both NFPA 90-A and ICC AC167.

1.04 WARRANTY

A. Manufacturer must provide a 10 Year Product Warranty for products supplied for the fabric portion of this system as well as a Design and Performance Warranty.

1.05 DELIVERY, STORAGE AND HANDLING:

A. Protect fabric air dispersion systems from damage during shipping, storage and handling.

B. Where possible, store products inside and protect from weather. Where necessary to store outside, store above grade and enclose with a vented waterproof wrapping.

PART 2 – PRODUCTS

2.01 MANUFACTURER:

Subject to compliance with requirements, provide products manufactured in the United States, choose one of the following:

A. DuctSox® Corporation

4343 Chavenelle Road

Dubuque, IA 52002

Phone: (866) DUCTSOX or (563) 589-2777

FAX: (866) 398-1646 or (563) 589-2754

www.ductsox.com

2.02 FABRIC AIR DISPERSION SYSTEM:

A. Coronado Fabric: Air diffusers shall be constructed of a woven fire retardant fabric complying with the following physical characteristics:

1. Fabric Construction: 100% Flame Retardant and treated with a machine wash-able anti-microbial agent from the manufacturer.

2. Weight: 6.75 oz. /yd2 per ASTM D3776

3. Pattern: (Galvanized, Harvest, Cork, Camo or custom)

4. Air Permeability: 2 (+2/-1) cfm/ft2 per ASTM D737, Frazier

5. Temperature Range: 0 degrees F to 180 degrees F

6. Fire Retardancy: Classified by Underwriters Laboratories in accordance with the flame spread/smoke developed requirements of NFPA 90-A and ICC AC167.

7. Antimicrobial agent shall be proven 99% effective after 10 laundry cycles per AATCC Test Method 100.

B. SYSTEMS FABRICATION REQUIREMENTS:

1. Air dispersion accomplished by linear vent and permeable fabric. Linear vent is to consist of an array of open orifices rather than a mesh style vent to reduce maintenance requirements of mesh style vents. Linear vents should also be designed to minimize dusting on fabric surface.

2. Size of vent openings and location of linear vents to be specified and approved by manufacturer.

3. Inlet connection to metal duct via fabric draw band with anchor patches as supplied by manufacturer. Anchor patches to be secured to metal duct via. zip screw fastener – supplied by contractor.

4. Inlet connection includes zipper for easy removal / maintenance.

5. Lengths to include required zippers as specified by manufacturer.

6. System to include Adjustable Flow Devices to balance turbulence, airflow and distribution as needed. Flow restriction device shall include ability to adjust the airflow resistance from 0.06 – 0.60 in w.g. static pressure at 1,600 FPM.

7. End cap includes zipper for easy maintenance.

8. Fabric system shall include connectors to accommodate suspension system listed below.

9. Any deviation from a straight run shall be made using a gored elbow or an efficiency tee. Normal 90 degree elbows are 5 gores and the radius of the elbow is 1.5 times the diameter of the DuctSox.

C. DESIGN PARAMETERS:

1. Use fabric diffusers only for positive pressure air distribution components of the mechanical ventilation system.

2. Do not use fabric diffusers in concealed locations.

3. Fabric diffusers shall be designed from 0.25” water gage minimum to 3.0” maximum, with 0.5” as the standard.

2. Fabric air diffusers shall be limited to design temperatures between 0 degrees F and 180 degrees F (-17.8 degrees C and 82 degrees C).

3. Design CFM, static pressure and diffuser length shall be designed or approved by the manufacturer.

D. SUSPENSION HARDWARE: (include applicable components only)

- 1. Tension Cable: System shall be installed using a tension cable system including a single (1 Row) or double strands (2 Row) of cable located 3” above top-dead-center (1 Row) or 3” above the 10 and 2 o’clock locations of the DuctSox system. 2 Row supports are required for systems of 32” diameter and larger. Hardware to include cable, eye bolts, cable clamps and turnbuckle(s) as required. System attachment shall be made using nylon snap clips spaced 24 inches. Component options include (must specify per area if multiple on same project):

1. Galvanized Steel Cable

2. Stainless Steel Cable

3. Plastic Coated Stainless Steel Cable

- 2. 3×1 Suspension: (Available on duct diameters from 16” to 48”) System shall include a 3 Row connection to fabric system at 10, 12, and 2 o’clock locations. Attachment spacing is not to exceed 3 feet. The powder-coated aluminum hangers are secured and integrated to a single (1 Row) tension cable every 3’ and connect to the fabric system at the 10 and 2 o’clock locations with detachable D-Clasps. The fabric system will also have clips located at 12 o’clock to attach directly to the single tension cable system located 3” above top-dead-center location of the fabric system. Tension cable hardware to include cable, eye bolts, cable clamps, and turnbuckles as required. Component options include:

- a. Galvanized Steel Cable

- b. Stainless Steel Cable

- 3. Suspended H-Track: System shall include a single (1 Row) or double (2 Row) runs of aluminum H-Track system located 1.5” above top-dead-center (1 Row) or 1.5” above the 10 and 2 o’clock (2 Row) locations of DuctSox system. 2 Row supports are required for systems of 32” diameter and larger. Hardware to include 10’ sections of track, splice connectors, track endcaps and vertical cable support kits – consisting of a length of cable with a locking stud end and Gripple quick cable connectors. Radius aluminum track must be included for all radius sections.

Fabric / Track attachment

- a. Cord In continuous supporting cord (not suggested for systems >24” Dia.)

b. Snap Tabs are a detachable sliding tab positioned every 24” along the length of the system (all diameters).

Hardware components (optional)

a. Provide 316 Stainless Steel components including coupler assembly, vertical cable support and Gripple quick cable connector.

- 4. Flush-Mount Track: System shall include aluminum Flush-Mount system located 1.5” above top-dead-center of DuctSox system. Hardware to include 12’ section of track, Snap Tabs, splice connections and end caps as required. Snap Tabs must promote easy sliding movement through aluminum track and must be detachable from the fabric. Radius aluminum track for support of the elbows through the corners using either Snap Tabs or Cord-In.

Fabric / Track attachment

- a. Cord In continuous supporting cord (not suggested for systems >24” Dia.)

b. Snap Tabs are a detachable sliding tab positioned every 24” along the length of the system (all diameters).

- 5. Surface Mount: System shall include aluminum Flush-Mount system located flush with the top of DuctSox system. Width between mounting points (of the track to the ceiling) shall be 2” wider than the specified diameter of the D-Shape DuctSox. Hardware to include 12’ sections of track, splice connections and end caps as required. System attachment shall be made by cord sewn into top side flaps of DuctSox system supported entire length.

PART 3 – INSTALLATION

3.01 INSTALLATION OF FABRIC AIR DISPERSION SYSTEM:

A. Install chosen suspension system in accordance with the requirements of the manufacturer. Instructions for installation shall be provided by the manufacturer with product.

3.02 CLEANING AND PROTECTION:

A. Clean air handling unit and ductwork prior to the DuctSox system unit-by-unit as it is installed. Clean external surfaces of foreign substance which may cause corrosive deterioration of facing.

B. Temporary Closure: At ends of ducts which are not connected to equipment or distribution devices at time of ductwork installation, cover with polyethylene film or other covering which will keep the system clean until installation is completed.

C. If DuctSox systems become soiled during installation, they should be removed and cleaned following the manufacturers standard terms of laundry.

Photo Gallery

DRUMMONDVILLE – October 7th, 2014 – Aeronergie, whose corporate mission to lower energy consumption and greenhouse gas emissions in air

For over 15 years, Enerconcept Technologies has brought fresh air into buildings. Now, Enerconcept brings light! Enerconcept Technologies is proud

During the AHR Expo in New York City in January 2014, Mr. Cary Pinkalla, president of DuctSox, presented the DuctSox

Magog, November 28th 2013 Contech 2013 Innovation and Sustainable Development awards – Enerconcept technologies is awarded the Sustainable Development grand

FOR IMMEDIATE RELEASE Magog’s Tennis Club and Fitness Center innovates and becomes eco-responsible with the installation of a solar air